We’re excited to officially share that we’ve moved into a new, expanded facility and are fully operational at our new location: 📍41743 Haggerty...

Stop the Banging and Breakdowns: Fix Water Hammer for Good

Water hammer is one of the most disruptive and expensive problems in industrial fluid systems—yet it’s also one of the most preventable. At Professional Pump, we help facilities identify the root cause of water hammer and implement engineered solutions that protect equipment, reduce downtime, and keep production on schedule.

Below, we break down what water hammer is, why it happens, and how we help facilities eliminate it—featuring a real-world example from a food and beverage company that faced recurring failures.

What is Water Hammer?

Water hammer occurs when the movement of liquid inside a pipe changes suddenly—typically caused by a fast valve closure, pump shutdown, or a sudden change in flow direction. When momentum stops abruptly, the energy has nowhere to go except back through the piping system as a high-pressure shockwave.

These pressure spikes can exceed the mechanical limits of valves, pumps, gaskets, fittings, and instrumentation. Common symptoms include:

- Loud banging or knocking sounds in piping

- Pipe vibration or shaking equipment

- Premature valve, gasket, or instrument failures

- Unexplained system shutdowns

- Recurring maintenance around the same areas of the plant

Left unaddressed, water hammer can cause catastrophic failures and costly downtime.

Case Study: Eliminating Costly Failures at a Food & Beverage Facility

A fast-growing food and beverage producer began experiencing repeated failures in its chilled water and CIP systems. Operators noticed:

- Sharp banging noises throughout the process lines

- Excessive vibration

- Frequent damage to valves, gaskets, and instrumentation

Production was forced to stop repeatedly to replace failed components—leading to costly downtime and increased risk of product loss.

Professional Pump evaluated the system and determine why these failures were occurring.

Root Cause: Water Hammer

A review of system operation revealed that water hammer was the culprit. Several contributing factors were identified:

- Fast-closing valves stopping flow abruptly

- Slow-closing swing check valves, causing reverse-momentum slamming

- Pump shutdowns creating rapid velocity changes

- Undersized pipe supports, unable to handle shock loads

These transient pressure spikes were exceeding the system’s mechanical limits and directly causing the repeated failures.

Professional Pump’s Recommended Solution

Professional Pump proposed a comprehensive mitigation plan designed to control forward and reverse momentum, stabilize the piping system, and prevent future failures.

Forward-Momentum Control

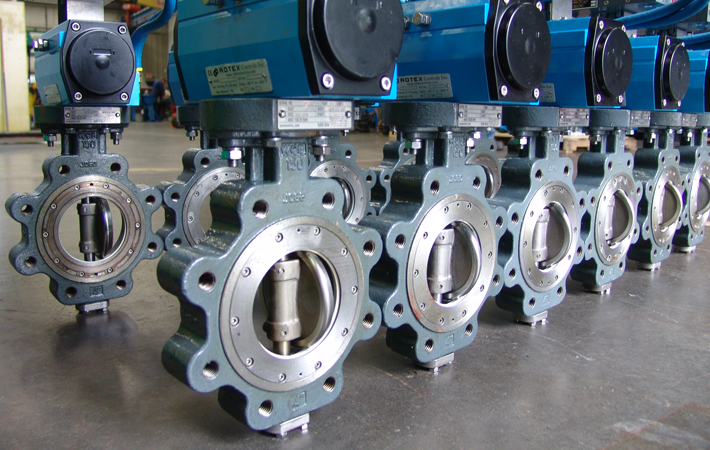

- Adjusting pneumatic valve closing speeds

- Recommending electric actuators with built-in deceleration

- Using needle valves to fine-tune actuation timing

Reverse-Momentum Protection

- Replacing swing checks with fast-acting, spring-assisted check valves

- Adjusting pump start/stop sequences to reduce hydraulic shock

Mechanical System Improvements

- Updating and reinforcing pipe supports in vibration-prone areas

- Introducing surge-reducing elements into a redesigned skid package

Collectively, these improvements were engineered to eliminate damaging pressure spikes and protect the system long-term.

Expected Results

With this solution in place, the facility would see:

- Significant reductions in maintenance and replacement costs

- Fewer production interruptions and smoother operation

- Extended equipment life across valves, pumps, and instrumentation

- Increased safety by reducing high-energy shock events

Facility leaders estimated substantial annual savings simply by avoiding unplanned downtime and premature component failures.

Protect Your Facility from Water Hammer

Water hammer can quietly damage equipment for months before the symptoms become severe. Professional Pump helps facilities pinpoint the true source, engineer a long-term fix, and prevent costly failures before they start.

If you’re seeing vibration, repeated valve failures, or unexplained shutdowns, water hammer may be the cause—and we can help.

Ready to stop water hammer before it stops production? Contact Professional Pump to schedule a system evaluation.

.jpg)