We’re excited to officially share that we’ve moved into a new, expanded facility and are fully operational at our new location: 📍41743 Haggerty...

Preparing for Plant Outages: A Smarter Approach to Valve Maintenance

Planned plant outages are critical moments for manufacturing facilities. They provide a rare opportunity to address reliability risks, improve performance, and reduce the likelihood of unplanned downtime once production resumes. The most successful outages are not reactive. They are carefully planned well in advance with clear priorities and defined outcomes.

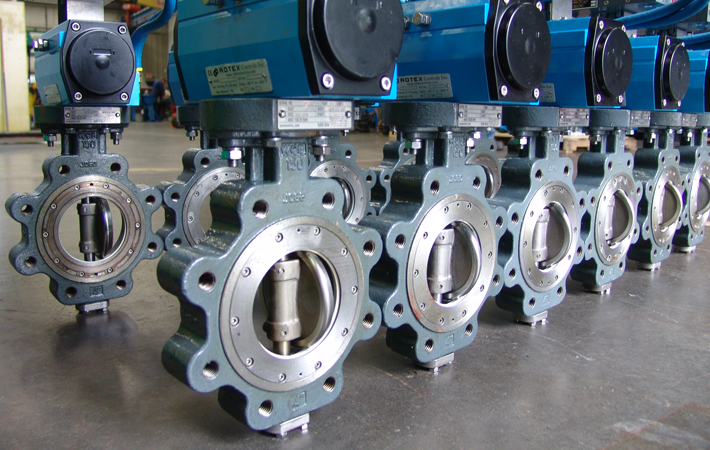

One area that consistently deserves attention during an outage is valve maintenance. Valves control the flow, pressure, and isolation of process systems. When valves wear, leak, or fail to operate properly, the impact can extend far beyond a single component. Addressing valve issues during a planned outage helps prevent emergency repairs, protects equipment, and supports smoother startup after the shutdown.

At Professional Pump, we work closely with maintenance, operations, and engineering teams to support outage preparation with a practical focus on valve reliability and system performance.

Why Valve Maintenance Should Be Part of Every Outage Plan

Valves operate under constant mechanical and process stress. Over time, seats and seals wear, internal components degrade, and actuation becomes inconsistent. These issues often go unnoticed during normal operations but can quickly lead to downtime or safety concerns if left unaddressed.

Including valve maintenance in outage planning helps plants: .jpg?width=375&height=249&name=increase-dairy%20plant-productivity-by-upgrading-your-valves%20(2).jpg)

- Reduce the risk of leaks and loss of containment

- Improve flow and pressure consistency

- Prevent damage to pumps and downstream equipment

- Extend the life of existing assets

- Control maintenance costs by avoiding emergency repairs

What to Plan for Before the Outage Begins

Effective outages start with preparation. Identifying priorities early allows teams to focus on the assets that matter most and avoid delays once production is offline.

Key planning considerations include:

- Valves that are critical to production or safety

- Equipment with recurring maintenance issues

- Assets approaching the end of their service life

- Parts and repair kits that require lead time

Professional Pump often supports pre-outage evaluations to help plants prioritize valve work and ensure the right parts and resources are available when the outage begins.

During the Outage: Inspection, Repair, and Replacement

With systems shut down, valves can be safely accessed, inspected, and serviced. This may include disassembly, replacement of worn components, cleaning, testing, or full valve replacement when repair is no longer cost effective.

Performing this work during a planned outage helps minimize startup issues and reduces the likelihood of unexpected failures once production restarts.

After Startup: Setting the Stage for Long Term Reliability

The value of an outage extends beyond the shutdown window. Documenting repairs, tracking valve condition, and identifying future maintenance needs helps plants move from reactive maintenance to a more predictable strategy.

Professional Pump supports customers before, during, and after outages with technical expertise, authorized parts, and on-site support. Our goal is to help plants get more value from every outage by improving reliability, reducing risk, and supporting long term performance.

.jpg)